We talk to a lot of contractors about fiber optic testing. One scenario we frequently encounter is contractors bidding work while only accounting for the time spent in the field splicing and testing. For one reason or another contractors seldom recognize the time required for trace analysis. A recent white paper released by a major test equipment manufacturer suggested that in-field testing was only 50% of the actual time invested to complete testing. The other 50% was spent at the office generating reports. Let’s take a closer look at the 50% required to generate final reports.

First we should address the statement of “50% of the time required is trace analysis.” This 50% of the time can be a deceiving number based on many factors which can come into play. A short list of factors which can affect the time required include : software, available skilled labor, custom reports and trace analysis experience, We will discuss each of these points in more detail below. What we want to address is the learning curve associated with these factors, which can significantly increase that initial “50% of the time for trace analysis.”

Software is a major component of the trace analysis process. Typically contractors work with only one brand of OTDR which can reduce the number of software packages needed. However, if your company works with multiple brands of OTDRs, owning multiple software packages may be necessary. To complicate the situation even further, a contractor may not be happy with the final report created at the end of the process. Now money has been invested for a program that does not necessarily fit the needs of the end user. Using a third party which specializes in trace analysis will allow the contractor to put the burden of report generation on the sub-contractor.

Another unforeseen expense of in-house trace analysis is teaching someone how to use the software package. The path that our company took required us to learn three different trace analysis software packages. We have endured a few challenges in this arena with one program taking over three days to learn before we generated our first report (and it didn’t look very good). That same program took approximately two more days to have the report template just how we wanted it for final delivery. Most people don’t have that kind of time to invest in trace analysis before starting the actual analysis.

Most companies are not overflowing with specialized skilled labor to perform work such as splicing and testing. That means a company may need to take a skilled worker out of the field in order to perform trace analysis for a project. Removing splicers and other skilled technicians from the field can slow down projects, cause delays and ultimately takes a person away from the work they are most productive at. Don’t forget that constantly shifting personnel around to fill gaps in the labor force can take a toll on workers and managers which can lead to high turn over rates for skilled workers.

In our experience as a trace analysis sub-contractor, we find many of our customers want to discuss the final report before our service and price is even agreed upon. In most cases the final reports that we deliver to major carriers will suffice for the majority of contractors. However, there are rare exceptions when a customer needs a truly custom report. Due to our experience creating reports for our own testing services we are able to create custom reports with a specific program or by using multiple programs to properly organize data.

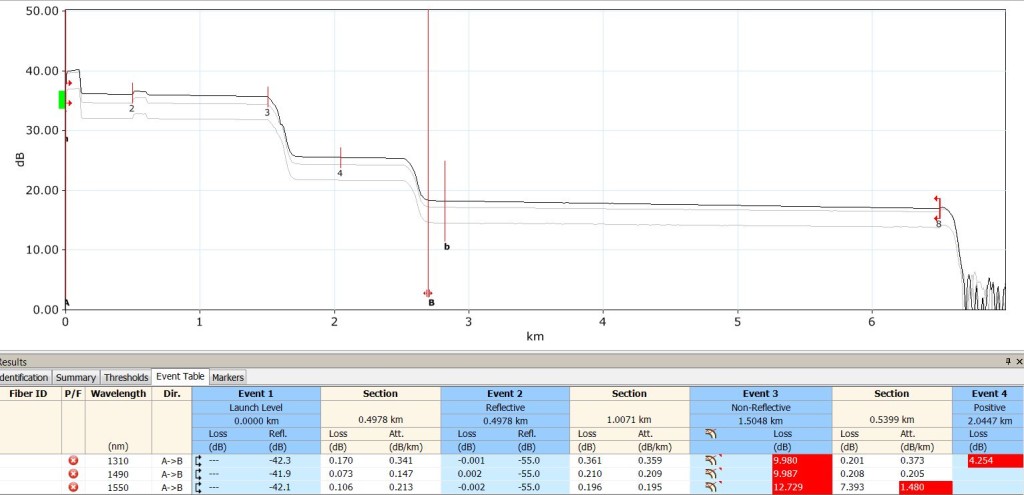

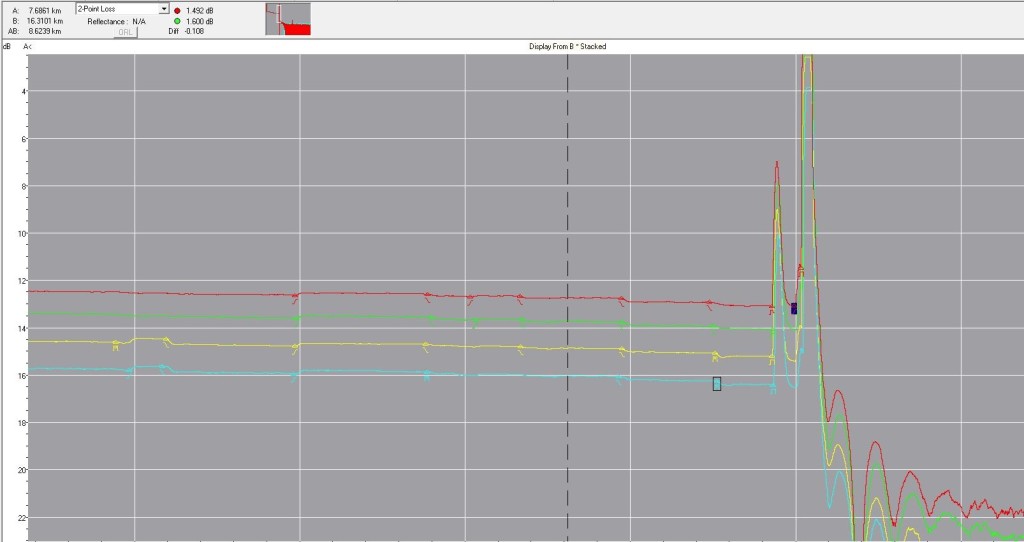

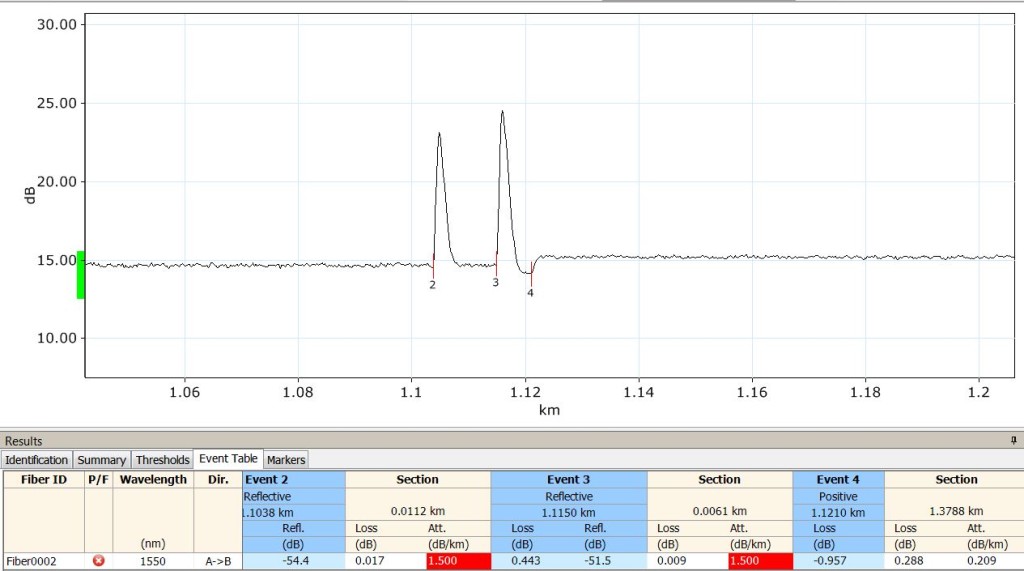

We previously discussed that learning a trace analysis program can be very time consuming. Recognize that using the program is only one part of the process. The other more important part of the trace analysis process is having a person who understands how to actually analyze traces. A variety of functions are required to properly prepare traces in order to identify any false or problematic events. Our trace analysis experts provide a final review of testing parameters, equipment information, all traces, averages and additional criteria. Understand that learning curve for trace analysis can be considerably longer than learning a program depending on the individual.

The benefits of having a specialized third party review your test results can be endless. In the past, we have found numerous issues with trace files which technicians did not recognize in the field. The most common issues we find are poor launch conditions, bad splices and connector reflectance issues. Our ability to identify issues and suggest corrective action is perhaps the most underrated portion of the service. Technicians that don’t have to troubleshoot and locate problems are much more efficient at correcting issues which saves time and money.

The next time you find yourself faced with a trace analysis project that is either overwhelming or just not going to fit into the schedule look at your options for sub-contracting trace analysis. If you work closely with a third party such as Legacy Fiberoptics, you may find the final reports are quite complementary to your end product and timeline. Contact our Professional Services group in order to discuss your current or upcoming project.